Production Locations

- Brussels, Belgium

Working Conditions & Living Wages

Each bag is handmade by An Vandenberk herself, directly in her Brussels studio. She is a certified Moroccan tailor and pattern designer, trained at Syntra Brussels. Thanks to her independent working method, she maintains full control over production, ensuring safe working conditions and fairer pay. There are no intermediaries or anonymous suppliers.

Her passion began early: at 14, she designed her first bag from old jeans and leather boots. That same creative energy continues to shape every design today.

Clients can visit her studio to co-design their perfect handbag.

Materials

- Upcycled leather (e.g. from old jackets or boots)

- Leather offcuts

- Leather from LWG Gold-certified European tanneries (upon request only)

- Water-based adhesives

An uses existing materials whenever possible, giving old leather new life and reducing the demand for newly produced animal leather. This helps minimise waste and makes resource use more efficient. Learn more about leather here.

Packaging

- For shipping, An uses recycled cardboard boxes to avoid generating new packaging waste.

- Bags can be collected directly from her studio or personally delivered by An, helping to reduce CO₂ emissions during transport.

Water Use & Chemicals

An Vandenberk carefully limits water and chemical use in her materials and processes. Instead of conventional solvent-based products, she opts for water-based adhesives, reducing harm to both the environment and health. Because she primarily works with upcycled or surplus leather, there is no need for additional processes such as dyeing, printing, or bleaching, further limiting chemical use.

When new leather is used at a client’s request, it comes exclusively from LWG Gold-certified European tanneries that meet strict standards for water and chemical management.

An also deliberately avoids synthetic leather alternatives due to concerns about microplastic release and recycling challenges. Learn more about the pros and cons of vegan leather here.

Circular Product Design

An’s designs focus on upcycling and creative reuse. Old leather jackets become new handbags, while leftover leather is transformed into small bags or accessories.

Circular Business Model

A repair service is available for all bags, extending their lifespan and reducing waste.

There is currently no take-back programme for end-of-life bags.

Distance & Supply Chain Complexity

- Production: Brussels, Belgium

- Material sourcing within Europe (Italy, France, Belgium, Netherlands)

- Headquarters: Brussels, Belgium

The entire value chain is short and local.

Transport

- Supply chain: Material transport takes place mainly locally and within Europe.

- E‑commerce: Orders can be collected at the studio or personally delivered by An within the local area, helping to avoid unnecessary transport emissions.

- Recycled/upcycled leather from jackets and remnants

- Leather from LWG Gold-certified European tanneries (upon request only)

An consciously avoids newly produced animal leather.

The brand prefers leather over vegan alternatives due to the risks of microplastic release and the limited recyclability of synthetic materials.

Product Design

An offers bespoke handbags and accessories that are durable and individually designed. Each piece is one-of-a-kind, crafted according to the client’s personal wishes. Her made-to-measure approach makes the designs inclusive and adaptable. Instead of standard sizes or collections, she creates pieces tailored to each person’s needs and style.

Slow Fashion Processes

Production is strictly made-to-order. There are no seasonal collections. Clients can even bring their own leather jackets to be transformed into new, unique creations.

In the past, a fashion collection was released in collaboration with Bamboo Belgium.

Product Transparency

Product pages describe the materials and design details.

Additionally, visitors learn on her website that all pieces are designed and handmade by An Vandenberk in her Brussels studio.

Regarding traceability, materials and production locations can be verified in general terms. However, there is no detailed, item-specific transparency (e.g. the exact origin of each piece of leather or individual suppliers).

Process Transparency

Clients are informed about material choices and design decisions, gaining a better understanding of the impact of conscious consumption.

No cost breakdowns or sustainability reports are publicly available.

Conclusion

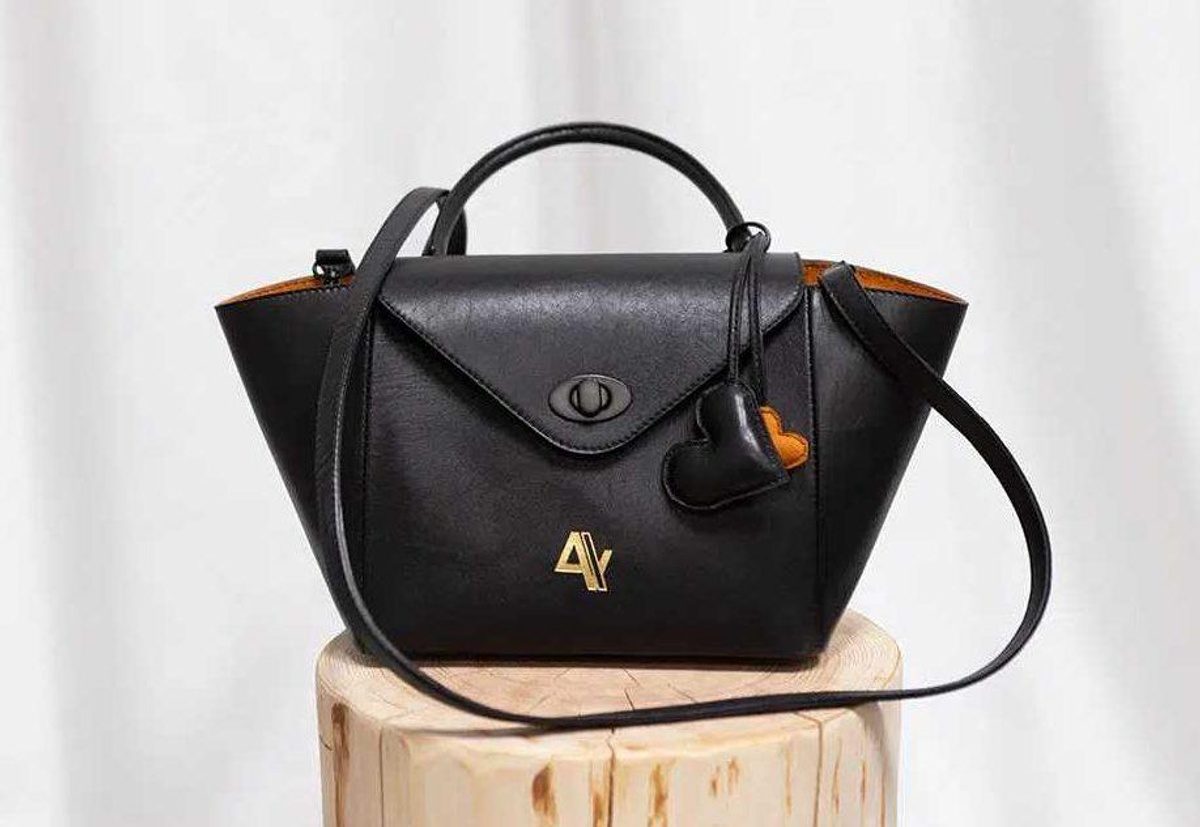

An Vandenberk’s collection of handbags, backpacks, and accessories stands out through handcrafted, individually tailored production. Discover how she transforms discarded leather and leather goods into unique, stylish designs. Each piece tells its own story and embodies distinct characters.